FLEX YOUR POWER ON THE FARM.

Innovation, technology and machinery designed to increase crop productivity are statements that have underlined GTS do Brasil as a trusted manufacturer of high-performance agricultural implements throughout the world.

GTS has always manufactured innovative cutting decks with a philosophy based on simplicity and efficiency. The use of strong lightweight materials such as aluminium increases performance and fuel economy, while reducing wear on the combine and soil compaction.

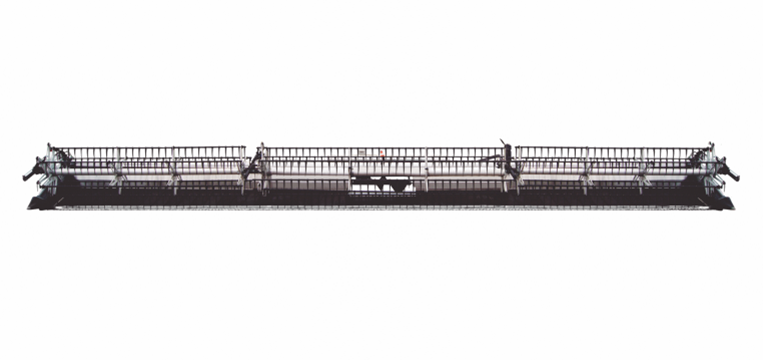

This commitment to ongoing innovation has resulted in GTS do Brasil launching the Flexer XS (40 feet).

The Flexer XS brings more productivity, the ability to work at greater speed, and provides a better cut with less loss of grain. It has a self-compensating floating system, allowing the cutter bar to slide smoothly over the ground and avoid drag. Additionally this machine reduces the wear of the platform and harvester, bringing superior results for large-scale harvesting.

Features

Cutter Bar

The cutter bar uses the EasyCut system from the renowned Schumacher brand. The Schumacher system, although simple, is quite precise, with the blades being placed alternately, one up and one down. Due to the placement and arrangement of the knives, the movement is smoother, and the bar is more stable.

Draper Mats

Rubber draper mats transport product smoothly. The centre belt and two sides all driven by an adjustable gearbox. The linear speed of the tracks can be varied via three speed settings with a variation of approximately 15% between the low, medium and high positions.

Hexagonal Reel

Featuring a hexagonal shaped reel, divided into three sections and constructed of high-strength steel. The position of the assembly can also adjust height and feed in relation to the cutter bar and rotation, proportional to the machine’s feed speed.

SpringFlex® flotation system

SpringFlex® flotation system is very responsive due to the sensors being directly under the cutter bar, instead of trailing behind, which then allows the perfect profiling of the soil and terrain even in the most extreme harvest conditions such as high humidity.

Flip Over Reel Bars in 3 Sections

Allow the operator to better visualise the cutter bar performance during harvesting.

Lightness & Flexibility

Increased performance thanks to a lighter, more efficient, and flexible harvesting system. The GTS do Brasil Flexer XS the perfect harvesting upgrade for farmers looking to improve results.

Go Even BIGGER!

Aside from all the features GTS have to offer, the Flexer XS is also available in bigger sizes. Ranging from from 40ft, to 50ft and even as big as 60ft! Pre-orders welcome.

Specifications

BRAND

GTS DO BRASIL

WORKING WIDTH

12.20 m

TOTAL WIDTH

13.10 m

WEIGHT

3580 kg

MATERIAL

Aluminium

REEL SECTIONS

3

KNIFE DRIVES

Double

READY TO ORDER?

Request a Price, Delivered to your farm

or Ask us for More Info

Not quite what you were looking for?

You May Also Like

Celikel H6 Horizontal Feed Mixer

PRICE ON APPLICATIONCelikel V14 Vertical Feed Mixer

Price on ApplicationGTS DO BRASIL Planner 510 Construction Drag Grader

$58,000 ex. GST$63,800 inc. GST

APV MDD 100 M1 – Bait Spreading (Multi-Metering System)

$6,800 ex. GST$7,480 inc. GST