GROUND BREAKING AUSTRALIAN TECHNOLOGY

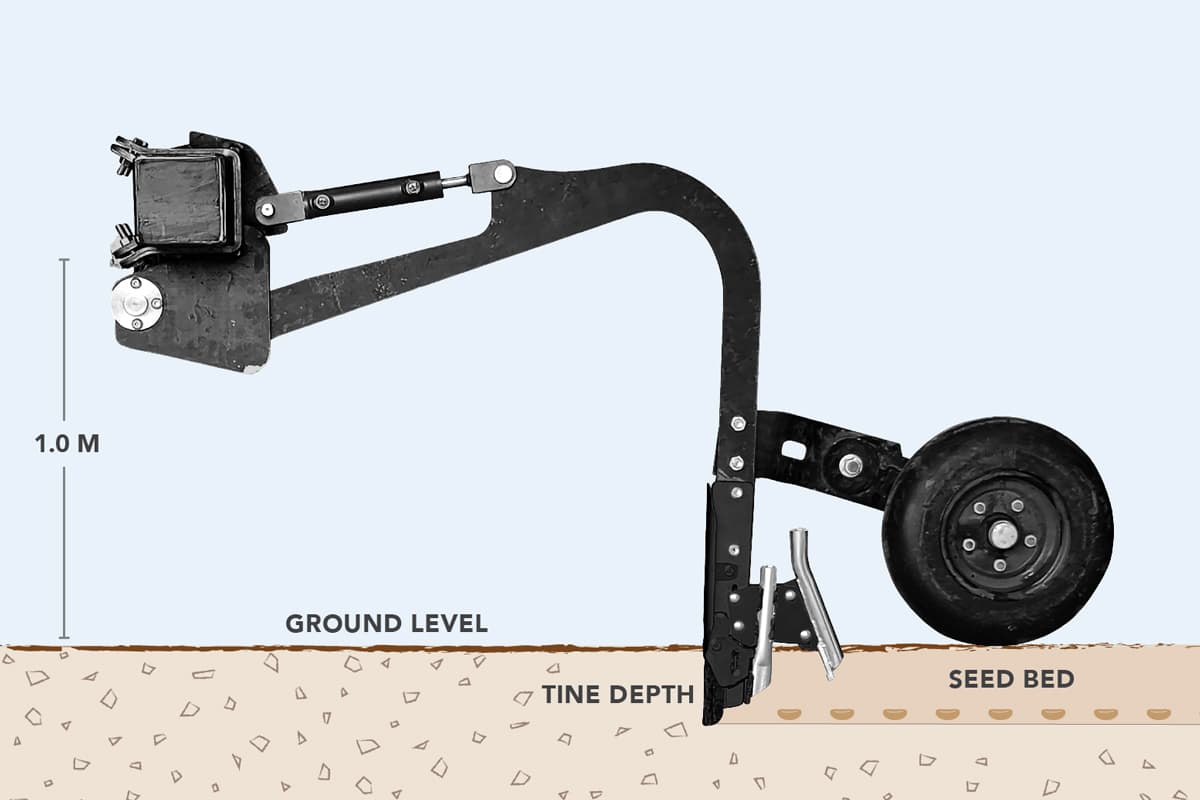

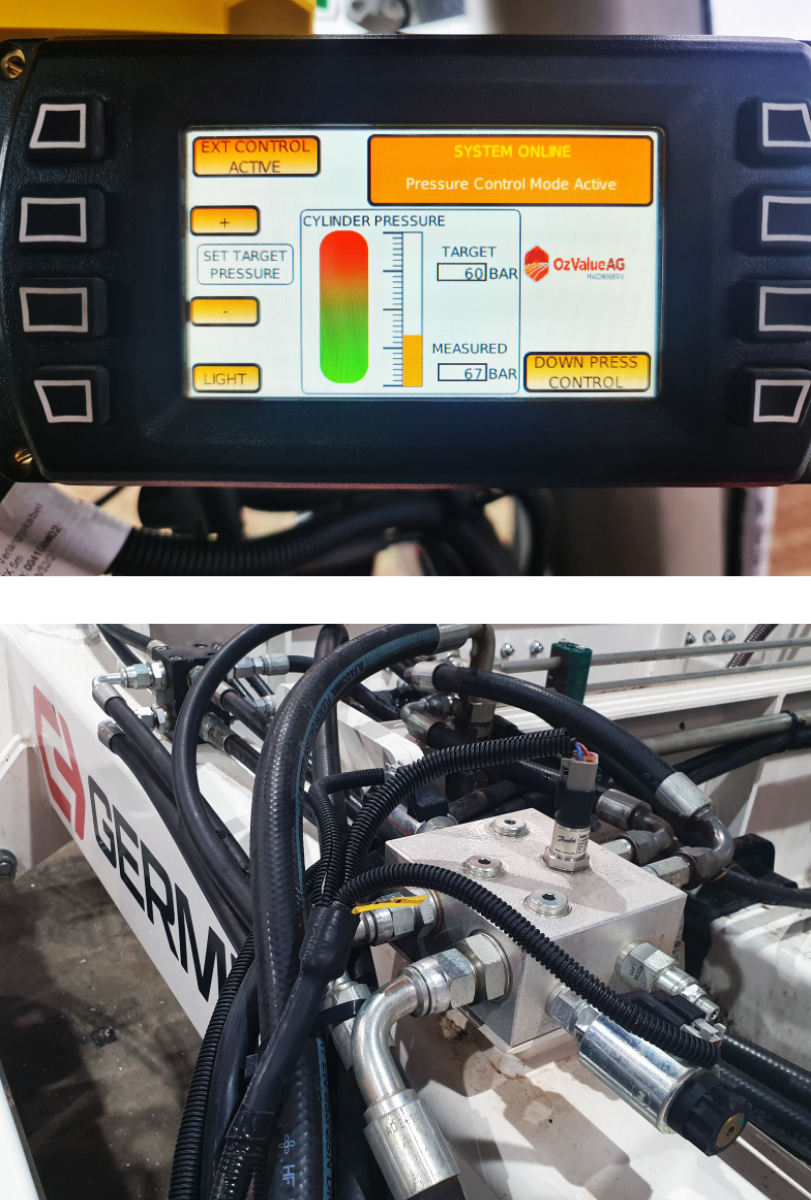

The Germinator features a unique single trailing tine with individual press wheel depth control, this allows each tine to follow the ground uniformly, even in undulating conditions, thus creating the ideal seed placement. Each tine is held in the ground with a hydraulic cylinder all controlled by a hydraulic manifold. Tine pressure can be adjusted from within the tractor cabin via a simple dial. All tines can be lifted and lowered using one hydraulic lever, in a similar way to most modern seeders and combines.

Frequently Asked Questions

Australian designed and assembled here in Australia in Ballarat Victoria.

Features

Easy Transport

Move with ease, with a 3.7m transport width^, the Germinator can be moved on your own, without the need for an escort* day or night in order to keep the machine sowing.

*Depending on your state legislation. ^Subject to Points, Attachments etc.

Tine Layouts

Throughout the design process, our focus was always on placing tines in the ideal pattern for trash flow.

One of the biggest challenges facing the modern farmer is the ability to sow through trash, so the bar has been designed so maximum spacing between the tines can be achieved in both directions, and pinch points are minimised.

750mm between each tine and 1070mm between rows when coupled with optional coulters, provides the best trash flow possible.

Specifications

BRAND

Oz Value AG

WORKING WIDTH

9.0 m

TRANSPORT WIDTH

3.7 m (subject to points, attachments etc.)

TRANSPORT HEIGHT

4.0 m

WEIGHT

10 T

READY TO ORDER?

Request a Price, Delivered to your farm

or Ask us for More Info

Not quite what you were looking for?

You May Also Like

Celikel H8 Horizontal Feed Mixer

Price on ApplicationCelikel H10 Horizontal Feed Mixer

Price on ApplicationFlatout TR-2016 20′ Twist Land Roller

$33,000 ex. GST$36,300 inc. GST