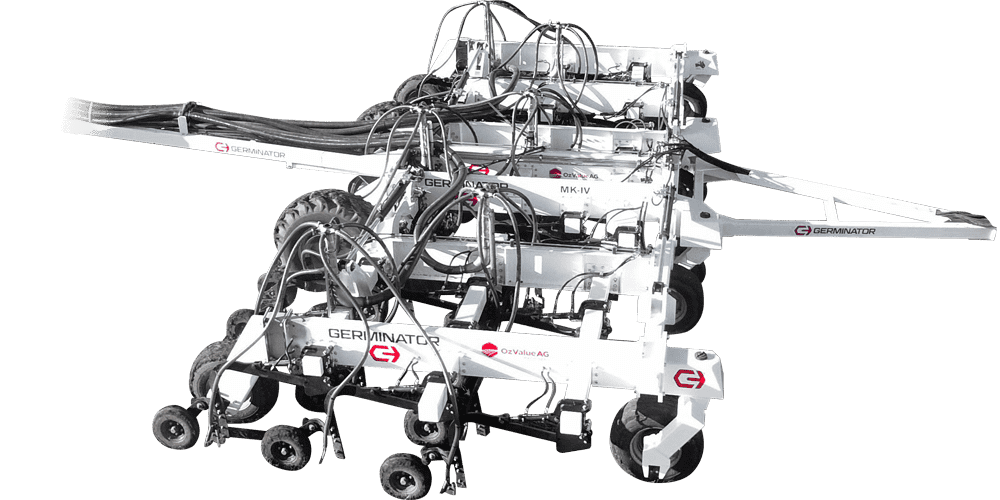

Germinator Air Seeder MK-IV

$0 ex. GST

$0 inc. GST

The Germinator‘s development was based on the experience of OzValue AG’s Directors when working on their own farms. Discussions with surrounding neighbours confirmed that they all wanted the same thing.

It’s with this knowledge, OzValue AG set about creating a workable solution to these needs, and after years of thorough development, now present the Germinator.

Widths

- 9.0m Working

- 3.7m Transport (subject to points, attachments etc.)

Description

The Germinator‘s development was based on the experience of OzValue AG’s Directors when working on their own farms. Discussions with neighbours confirmed that they all wanted the same thing.

All wanted a machine that would do a handful of jobs. Place seed precisely, have good trash flow, have minimal moving parts, a good transport width, and of course all at a reasonable price.

These conversations continued around what available machines could and couldn’t do, and what the requirements of a new machine might be. OzValue AG then researched the pros and cons of the current range of machines and what features made certain models popular.

It’s with this knowledge, OzValue AG

set about creating a workable solution to these needs, and after years of thorough development, now present

the Germinator.

The Germinator features a unique single trailing tine with individual press wheel depth control, this allows each tine to follow the ground uniformly, even in undulating conditions, thus creating the ideal seed placement. Each tine is held in the ground with a hydraulic cylinder all controlled by a hydraulic manifold. Tine pressure can be adjusted from within the tractor cabin via a simple dial. All tines can be lifted and lowered using one hydraulic lever, in a similar way to most modern seeders and combines.

The 9m toolbar also incorporates optional sowing coulters. Constructed in pairs and mounted on rubber suspension, these coulters are similar to many modern high speed tillers. In addition, the frame has a 1m clearance whilst in the working position, this high tine clearance, symmetrical tine layout and precisely engineered frame, gives the best trash flow possible.

One of the biggest challenges was to fit all of these features into the toolbar and stay within the ideal dimensions set out the start of the project, as the team were conscious of how difficult it is becoming to move wide or high machinery around in our ever growing regions. It was decided that it was essential that the machine could be ideally moved on your own without the need for an escort* day or night in order to keep the machine sowing.

A common complaint with modern machines that to have all these features means many moving parts. For this reason the opener has been fitted with maintenance free ‘igus’ bushes. These plastic polymer bushes require no grease or lubricant, and can be easily changed without the need of a press or specialty tooling. This bush is a common component across the majority of pivot points on the Germinator and can be replaced for a fraction of the price when compared with other openers.

Many years of research, development, testing and refinement has lead us to the creation of the Germinator. With a balance of local knowledge and engineering, and sourcing the very best components from around the world and Australia, we’ve developed a groundbreaking solution for many farmers.

*Depending on your state legislation.

Additional information

| Weight | 568092394 kg |

|---|---|

| Dimensions | 5680945940 mm |